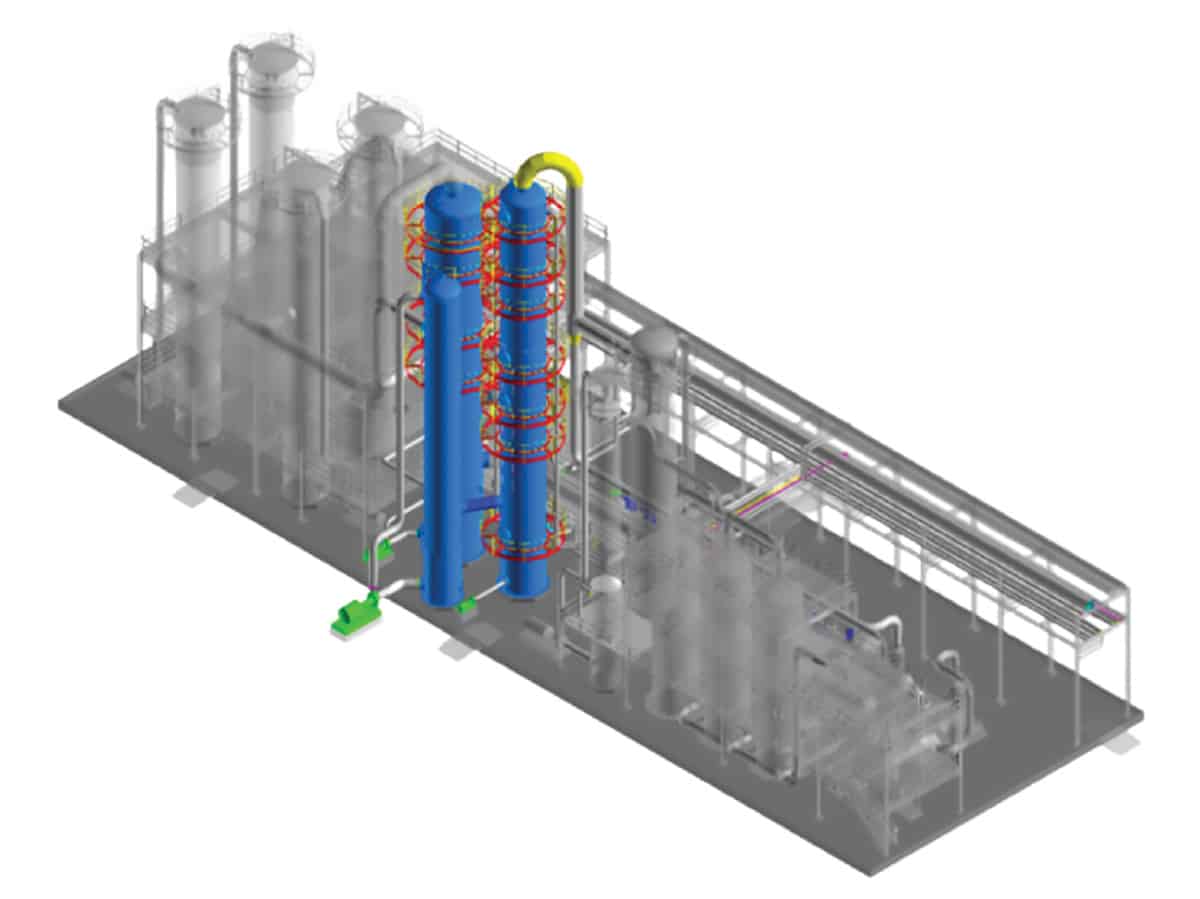

LOW ENERGY USAGE DISTILLATION (LED™)

Lower energy usage

Low Energy Distillation™ (LED) is FQT’s distillation solution to significantly reduce energy usage and downtime. The patented LED technology can be used to upgrade both pressure and vacuum distillation systems. The system eliminates the need for direct inject steam in distillation by utilizing more efficient equipment setup reducing overall energy load.

An additional benefit of the LED system is facilities can CIP evaporator and reboilers while running at full rate, thus reducing downtime. This increase in uptime helps facilities to achieve higher throughput, lowering OPEX per gallon. LED can reduce a plant’s steam usage by as much as 40%, resulting in lower energy consumption than any traditional pressure or vacuum design. LED energy savings and lower OPEX help to drive a plant’s CI score lower.

Lower temperature vacuum distillation reduces column fouling, thus reducing CIP needs. The increased plant uptime allows operations teams to limit shutdown frequency to as little as annually.

- Lower CI

- Eliminate downtime due to CIP

- Reduce steam usage by:

-up to 40%

-as low as ~8.6lbs/gal - Industry-leading OPEX for any distillation type

- Increased throughput

- Reduces water load

- New beer column, case by case

- New reboilers