Solutions

We deliver clean promises to help you keep yours

Fluid Quip Technologies is committed to building a better, more efficient, cleaner and more sustainable future. That’s why the bioeconomy leaders look to us for innovative solutions to help achieve their goals.

PUT DECADES OF EXPERIENCE TO WORK IN YOUR PLANT

Looking for insight and advice on process improvements, optimization, and design? Fluid Quip Technologies engineers bring decades of real-world knowledge gathered in the field.

Build it right for the long term

For construction management or even full turn-key projects, you won’t find another group with the expertise and field-proven experience of Fluid Quip Technologies.

We’ve managed new plant construction and expansion around the world, and will oversee full turn-key projects in the field. Fluid Quip Technologies offers support for capital projects such as fermenter additions and mole sieve expansions, and can also engineer and install new product technologies.

Latest Projects

Fluid Quip Technologies to Supply World’s First Wheat-Based MSC Protein System

Fluid Quip Technologies to Supply World’s First Wheat-Based MSC Protein System CEDAR RAPIDS, Iowa--(BUSINESS WIRE)-- Fluid Quip Technologies (FQT), a global leader in advanced biofuel, biochemical, and innovative co-product technologies, announced today that it will...

Engineering Solutions

Engineering SolutionsThe Fluid Quip Technologies (FQT) team of over 25 chemical and mechanical engineers bring decades of experience in ethanol plant design and operations to our customers. The team’s unique skill sets allow them to provide insights and guidance on...

Bolt-On Technology and Equipment

- Replacement/modification in-kind to all plant designs

- Compatible with vaccum or pressure distillation designs

- Design modification to existing beer column, rectification and stripping column; increases capacity up to 10-20%

Full Plant Benefits

- Up to 40% lower energy than competing system

- Potential reduced overall CI score

- Lowest product impurity levels

- No additional water required

- Reduced backset/water

GNS ALCOHOL

- Ultra pure quality levels

- Beverage grade

- A greener alternative

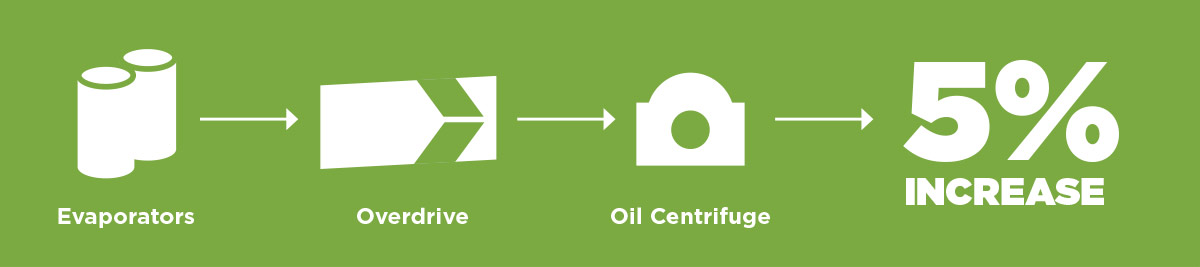

Get more oil out of the corn you grind

The Overdrive™ System from Fluid Quip Technologies is shown to increase oil production by 5% or more.

A revolutionary corn oil pre-treatment system that boosts the performance of existing distillers corn oil separation systems, creating the optimal conditions for maximizing oil yield.

You can change the result without changing the system.

- Boost gain: Increase oil yield 5% or more.

- Modular skid: Fast installation and easy maintenance.

- Designed for full automated control.

- Redundant design to ensure uptime and keep production flowing.

The technology behind the scenes.

Overdrive’s proprietary process gently conditions the syrup for optimal performance to amplify oil recovery. Smart, redundant design ensures uptime to keep production flowing.

What will 5% more oil mean to your bottom line?

Today can be the day you find out. Can you afford to wait?

A proven way to gain more Corn oil from your ethanol production process

Demonstrated performance through years of testing in our protein systems, this technology encompasses a multi-stage fiber washing with thin stillage clarification. A series of washing and clarification steps provide additional opportunities for the corn oil to be separated from the fiber for collection by the plant’s existing oil recovery system. Centrate from the fiber washing is sent to a final separation step to partition free oil from residual solids, producing an evaporator feed high in oil and low in suspended solids.

Because the DCO Technology™ system uses a fraction of the MSC™ patented protein separation technology, it is substantially less expensive. DCO Technology is housed within a new process building, constructed independent of the existing plant. This new building can be easily expanded to house the full MSC system when needed. A smaller footprint and streamlined equipment process means a relatively short construction timeline; as a result, biofuels facilities can quickly take advantage of rising oil values.

DCO Technology has many stand-alone benefits today, and can be a significant step toward the MSC protein system tomorrow.

Short build time, rapid payback

Project Details:

-

Bolt-on proven technology and equipment

-

Short construction and design time leads to faster return

-

FQT-designed engineering reliability and performance

-

New stand-alone building with a relatively short construction timeframe

Full Plant Benefits:

-

Reduced enzyme cost/usage, saving millions per year

-

Backset clarification, with potential lowered unfermented solids

-

Potential backset organic acid reduction

-

Healthier fermentation

-

Lower suspended solids in evaporator stream

-

Proven performance-technology running full-scale in multiple plants

-

A significant step toward the MSC protein system

-

Streamlined system operation and maintenance

MSC™: U.S. Patents: 8,778,433, 8,813,973, 9,066,531, 9,963,671, 10,160,932, 10,190,076, 10,233,404, 10,266,790, 10,519,398, 10,800,994, 10,875,889, 10,926,267, 10,995,346, 11,220,663, 11,230,504, 11,427,784, 11,603,507 and EP 2410869 and Canada: 2,763,476

DCO Technology utilizes multiple washing and separation systems to liberate additional distillers corn oil typically left on the fiber fraction in the DDGS. DCO Technology was born from FQT’s patented MSC protein separation system and is integral to the high corn oil yields obtained with MSC systems.

find out how much more oil you could be getting!

Protein production to produce more revenue

Now you can produce a high-quality alternative protein product from your operation, diversifying your plant’s revenue stream. Fluid Quip Technologies can get you there quickly.

click to enlarge image

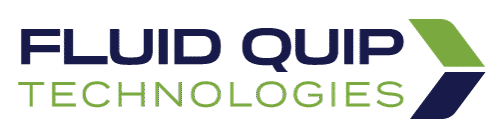

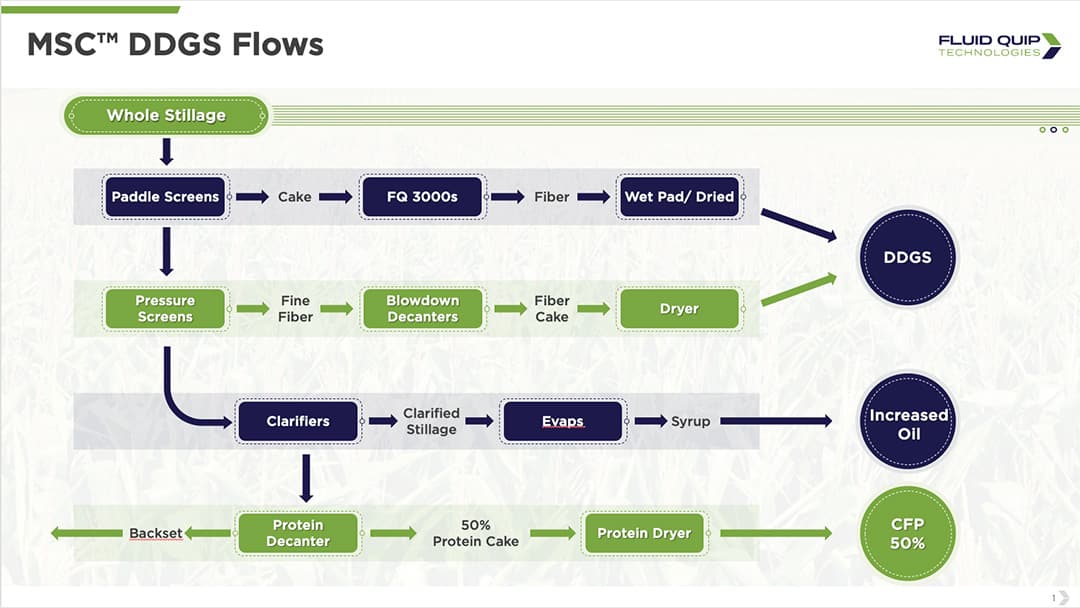

MSC™ Maximized Stillage Co-products

- Improves DDGS quality/value

- Proven corn fermented protein

value above SBM - 8 plants in operations/

4 additional plants under construction - ~10% plant throughput gain

- >20% increase in oil yield

- ~$.10-$.20/gallon additional EBITDA

- Less than 3-year payback

click to enlarge image

Produce a high-value alternative protein product

MSC produces corn fermented protein, a 50% purity protein product that trades in the alternative high-value protein market and is a unique blend of spent brewer’s yeast and corn gluten meal. The protein has shown great success in the pet food, aqua, dairy, poultry, and swine markets. It’s an excellent way to significantly diversify your plant’s revenue stream.

MSC™: U.S. Patents: 8,778,433, 8,813,973, 9,066,531, 9,963,671, 10,160,932, 10,190,076, 10,233,404, 10,266,790, 10,519,398, 10,800,994, 10,875,889, 10,926,267, 10,995,346, 11,220,663, 11,230,504, 11,427,784, 11,603,507 and EP 2410869 and Canada: 2,763,476

PURE PERFORMANCE FROM HIGH PURITY SUGAR

Pure sugars are now purely affordable. Fluid Quip Technologies put you on the leading edge of production capabilities, enabling you to produce more value for more markets.

For Producers

CST™ Clean Sugar Technology – HIGH QUALITY, LOWER Carbon Intensity than traditional sources

- Produce a lower carbon intensive sugar stream

- Bolt-on commercially proven technology for ethanol plants

- Operating since 2016

Get an equivalent sugar quality to a corn wet mill process with a >40% carbon reduction. CST not only produces an industrial sugar stream, it also yields a high-value corn oil stream and can produce valuable animal feed products, including a high-purity protein. The renewable chemicals market is growing rapidly, requiring a significant carbohydrate source. Add this system to a current ethanol facility to provide a sugar slipstream to meet those needs and significantly diversify a plant’s revenue streams.

For Consumers

A Lower Carbon Solution

Lower carbon footprints throughout the process

Clean Sugar Technology allows a dry grind facility to take full advantage of all the starch that is brought into the plant. By stopping the fermentation process at a key point of the starch conversion process (prior to ethanol production) allows the plant to produce the exact same sugars that the biotechnical, industrial and food industries are using today – at a smaller carbon footprint and more value than traditional sugar processes. The remaining streams are processed through the MSC process to produce high value proteins.

CST™: U.S. Patents: 9,777,303 • 10,119,157 • 10,480,038 • 10,995,351 • 11,034,987 • 11,053,557 • 11,447,806 • 11,505,838 • 11,519,013 • 11,597,955 Brazil: BR102019004535-3 and EP 3121258.

%

lower carbon intensity than wet mill produced sugars

REDUCE CARBON FOOTPRINT

Fluid Quip Technologies has commercialized multiple patented technologies focused on enhancing the base corn-to-ethanol dry grind process and producing novel high-value feed/food products..

SGT™ Selective Grind Technology

-

Up to 3.0% increase in ethanol yield

-

Up to 22% increase in oil yield

-

Currently utilized in >2 billion gallons of annual production, globally

-

FQT paddle screens utilize a proprietary back-flush screen cleaning system, which can reduce labor

-

SGT reduces dough balling from slurry to achieve better corn flour water mixing, resulting in improved enzymatic activity

Increase ethanol and oil yields

The SGT system is installed in the mash cook process to expose more starch conversion to ethanol and to shear open the germ, releasing more renewable corn oil. This system reduces starch in dried distillers grains, reducing dryer loading while also increasing DDGS ProFat levels, depending on plant conditions. This allows for more oil to be recovered while maintaining a DDGS protein specification.

SGT™/FBP™ – U.S. Patents: 9,012,191 • 9,689,003 and Canada: 2,831,268, and China: ZL201280023265.2

FBP™ Fiber By-Pass System

- Remove fiber pre-fermentation

- Produce a cellulosic ethanol feedstock

- Increase fermenter capacity

- Up to 10% plant throughput gain

- Reduce distillation energy

Increase capacity

Fiber By-Pass separates fiber pre-fermentation for up to a 10% increase in fermenter capacity, boosting plant throughput. It can produce a pure fiber that is an excellent feedstock for cellulosic ethanol or industrial applications. Fiber can be recombined with stillage to produce traditional DDGS or sold separately achieving a higher-protein DDGS.

SGT™/FBP™ – U.S. Patents: 9,012,191 • 9,689,003 and Canada: 2,831,268, and China: ZL201280023265.2

BOS™ Brix Oil Separation

- High quality, low FFA oil (5-7% FFA)

- Recover front end and back end oil

- Total oil yield >1.0 lb/Bu

Recover corn oil from liquefaction

The BOS system separates free corn oil from liquefaction prior to fermentation. Recovering corn oil on the front end with BOS lowers the free oil content in fermentation. This allows for more oil extraction through fermentation and back-end oil yields are still significant.

BOS™: U.S. Patent: 9,732,302, China: ZL201180065801.0, and Europe: 2,646,164

LED

BTU / Gallon Energy Savings

SGT

%

DCO Oil gain

WFS

L/MT Ethanol Yields From Corn

YOUR PLANT DOESN’T STOP

WFS™ WET FRACTIONATION SYSTEM

- ~ 430-460L/MT ethanol yields from corn

- Short payback timeframe

- Removes corn fiber before fermentation

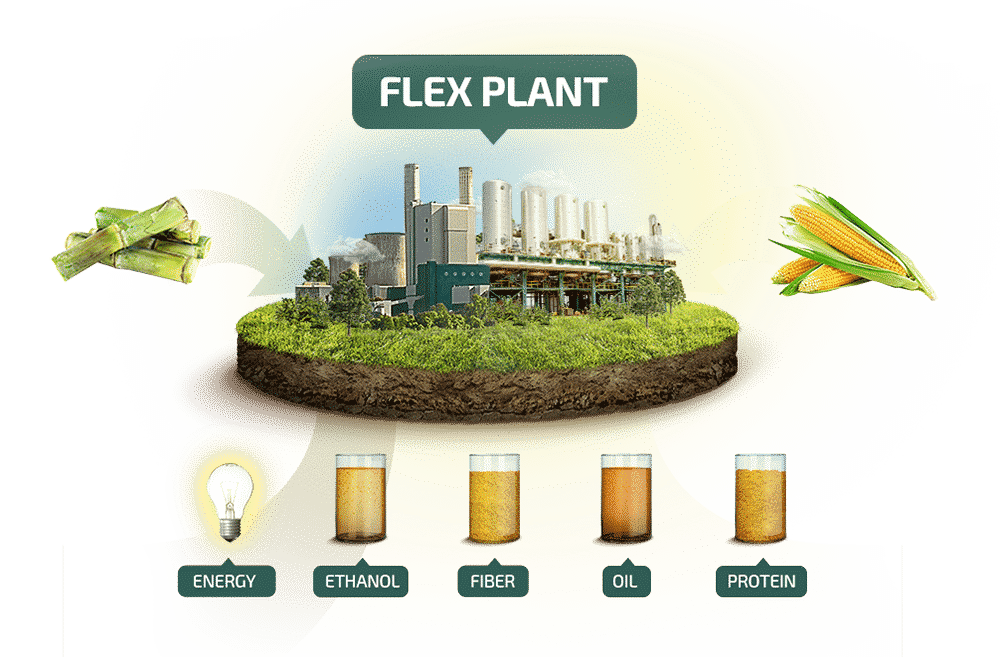

Blend corn with sugarcane as an ethanol feedstock

Integrate various FQT technologies for additive results, including SGT milling, BOS corn oil recovery, and FBP fiber separation. The WFS Flex Plant™ version produces a corn-based slurry stream without fiber, providing high yields of ethanol and co-products, and can blend into the existing sugarcane mill to utilize existing fermentation, distillation and evaporation. A facility can operate at full production capacity year-round.

WFS Flex Plant™: Patent Pending

LOW ATR AND RAINY DAYS WILL NOT BE A PROBLEM

As the standard FQT process removes corn fiber prior to fermentation, we have developed a solution that allows corn sugars to be fermented in exactly the same way as sugarcane sugars, optimizing the process on rainy days and days of low ATR.

We have adapted our process so that the sugarcane mill does not have to adapt. This will allow the plant to process 100% ethanol, which will significantly improve its profitability.

How it works

FQT technologies are additive, so they can be combined in varying orders and applications to get the exact milling/separation process your plant needs. This mix of standard yet customizable configurations reduces capital expenditures, eliminates frustrations, and won’t leave your investments stranded.

1. SGT™ Selective Grind Technology

FQT has SGT, a selective grinding patented system, in which the wet grinding is made in the liquefaction. This mill liberates more starch so it can be converted into sugars.

The plants that operate with this system achieve higher ethanol yields (from ~3 to 5%), higher oil yields, besides reducing the enzyme consumption. In South America the corn is harder, therefore the SGT yield in that region can bump the yields to ~7% more, which will be in a range of ~430 to 460 liters hydrous ethanol per ton of corn at 15% moisture.

2. FBP™ Fiber Bi-Pass System

FQT has developed the FBP to remove the corn fiber before fermentation. This way, the sugarcane mills can use the existing fermentation, distillation, and evaporation systems.

The corn fiber is sold for animal nutrition, similar to corn gluten meal.

3. BOS™ Brix Oil Separation

FQT has developed BOS for oil recuperation from liquefaction. This low FFA oil can be destined to animal nutrition or chemical uses. The total oil yield (front-end + back-end) on FQT process can exceed the ~18kg/ton.

4. MSC™ MAXIMIZED STILLAGE CO-PRODUCTS

The MSC system created by FQT to produce protein after fermentation. Is a 50% purity protein product and is negotiated as a protein of high value in the corn gluten and brewer’s yeast market.

Because running is everything

Around-the-clock service to keep your plant up and running.

Plant operations up-time is important to you, so it is important to us. That is why we have a full-service team of plant reliability experts with the experience to help you solve uptime issues, here to support you 24/7. Ready access to a full inventory and access to all Fluid Quip parts ensure that you maintain your plant’s uptime status.

Our team of maintenance technicians can help you to create comprehensive operational plans to decrease maintenance issues and downtime.

You have Questions. We have answers!

Latest News

Fluid Quip Technologies Delivering Strong Results with Low Energy, High-Quality Alcohol System at Three Rivers Energy

September 5, 2024 CEDAR RAPIDS, Iowa -- Fluid Quip Technologies (FQT), a global leader in advanced technologies for the biofuels, beverage alcohol and biochemical industries, announced strong results from their cutting-edge Low Energy Distillation™ (LED) and Grain...

Fluid Quip Technologies Announces Commissioning of World’s Largest MSC™ Protein System

Fluid Quip Technologies Announces Commissioning of World’s Largest MSC™ Protein System CEDAR RAPIDS, IA., July 30, 2024 – Fluid Quip Technologies (FQT) today announced the successful completion and commissioning of the world’s largest MSC™ System to date at Tharaldson...

Fluid Quip Technologies Announces Installation of Distillers Corn Oil (DCO) Technology™ System at CVEC Ethanol

Fluid Quip Technologies Announces Installation of Distillers Corn Oil (DCO) Technology™ System at CVEC Ethanol CEDAR RAPIDS, Iowa--(BUSINESS WIRE)-- Fluid Quip Technologies (FQT) proudly announces the integration of its groundbreaking Distillers Corn Oil (DCO)...

Fluid Quip Technologies’ DCO Technology™ Achieving Record Distillers Corn Oil Yields at Ace Ethanol

Fluid Quip Technologies’ DCO Technology™ Achieving Record Distillers Corn Oil Yields at Ace Ethanol CEDAR RAPIDS, Iowa--(BUSINESS WIRE)-- Fluid Quip Technologies (FQT) is pleased to announce that its patented Distillers Corn Oil (DCO) Technology™ is achieving record...

Fluid Quip Technologies to Supply World’s First Wheat-Based MSC Protein System

Fluid Quip Technologies to Supply World’s First Wheat-Based MSC Protein System CEDAR RAPIDS, Iowa--(BUSINESS WIRE)-- Fluid Quip Technologies (FQT), a global leader in advanced biofuel, biochemical, and innovative co-product technologies, announced today that it will...

Engineering Solutions

Engineering SolutionsThe Fluid Quip Technologies (FQT) team of over 25 chemical and mechanical engineers bring decades of experience in ethanol plant design and operations to our customers. The team’s unique skill sets allow them to provide insights and guidance on...