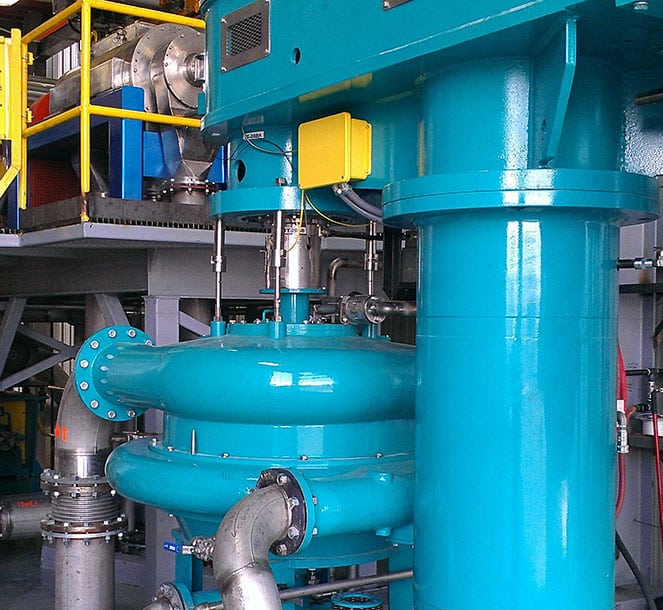

BOS™ Brix Oil Separation System

Client: Ace Ethanol, Stanley, WI

FQT provided technology, engineering, and key equipment supply for the patented BOS system at Ace Ethanol, at 45MMGY ethanol facility in Stanley, WI. This was FQT’s first BOS system worldwide recovering high quality, low FFA corn oil from liquefaction. The Ace BOS system utilizes the Fluid-Quip Triton centrifuge which treats the entire liquefaction stream in one centrifuge. Ace Ethanol had a high-yielding post-fermentation oil recovery system prior to installing the BOS system and since has achieved total oil yields well over 1.0lb/Bu.

“Fluid Quip Technologies has been a long-term partner with Ace Ethanol. They are innovative and bring a thorough understanding of plant design to improve performance. FQT has helped Ace be a technology leader in the industry. They provide proven FQT technologies, but also collaborate to work to improve other technologies with the plant’s best interest in mind.”

Neal Kemmet, President and General Manager, Ace Ethanol, Fox River Valley Ethanol

Triton Centrifuge

Corn Oil