NEW LOW-COST SUGAR FEEDSTOCKS

CLEAN SUGAR TECHNOLOGY (CST™)

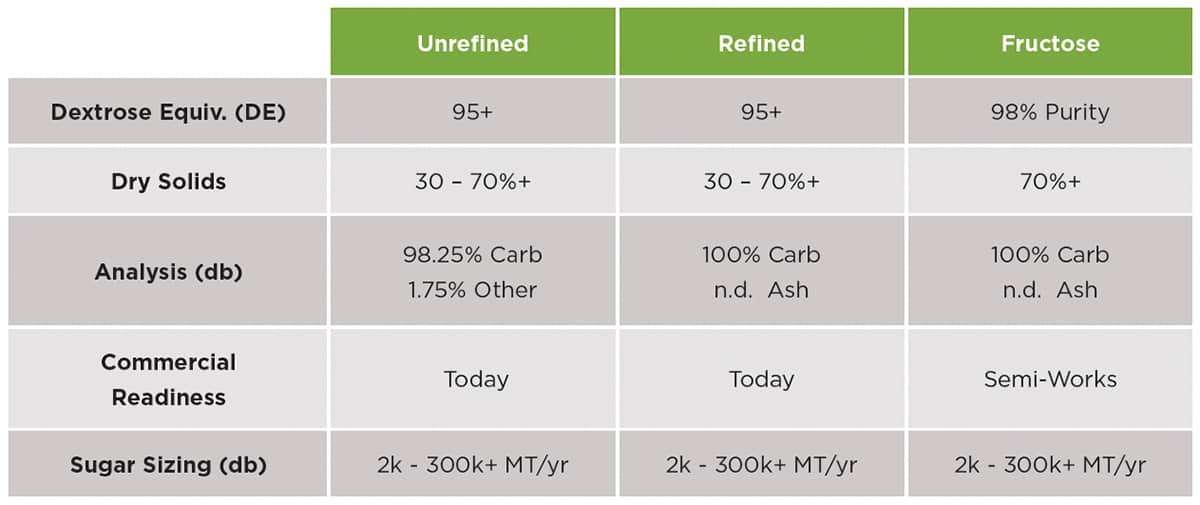

The renewable chemicals market is growing rapidly and requires a significant carbohydrate source. The Clean Sugar Technology system can provide that source while diversifying revenue for ethanol plants. CST produces an equivalent sugar quality to that of a corn wet mill process at up to 50% cost reduction. It can be bolted on to a current ethanol facility to provide a sugar slip-stream to meet those needs and significantly diversify a plant’s revenue streams. CST from FQT is here to change everything in the carbohydrate feedstock supply, with low volume at low cost. Using patented, proprietary separation equipment and systems, CST is effectively producing multiple specification, purity sugars for commercial use today.

Sugar feed-stocks available for

- Food Grade

- Industrial Grade

- Non-GMO

- Low-cost purified dextrose and fructose streams

- Global location opportunities without working through multinational corporations or levels of approvals of wet mills

- Proven, commercially ready process in commercial operation since 2016

- Bolt-on commercially proven technology for ethanol plants and stand alone systems

GAME CHANGING SUGAR SOURCE OPPORTUNTIY

Produces equivalent sugar quality to that of a corn wet mill process. Precise specifications at a specific purity at any location. Sugar available options for food grade, commercial grade, and Non-GMO.

Clean Sugar Technology provides a renewable chemical/bio-chem feedstock source at a huge cost savings, up to 50% less. We work directly with ownership teams at one of the 200+ available ethanol plant sugar sources in the US, or will apply a Clean Sugar solution at any facility, world-wide.

CST™: U.S. Patents: 9,777,303 • 10,119,157 • 10,480,038 • 10,995,351 • 11,034,987 • 11,053,557 • 11,447,806 • 11,505,838 • 11,519,013 • 11,597,955 Brazil: BR102019004535-3 and EP 3121258.